Mold and Tooling Systems

Poliya’s ZERO Tooling System offers long lasting, glossy molds with exceptional surface quality.

Mold and Tooling Systems

Green

Orange

Grey

Black

- Product Description

- Technical Data Sheets

- Safety Data Sheets

- Chemical Structure

-

Available Modifications

-

Viscosity

-

Barcol Hardness, 934

-

Gel Time

-

HDT [0,45 MPa]

- Density (gr/cm³)

- Remarks

- Highlights

- Primary Usages

- Polipol 321-ZERO

- ZERO System / Zero shrink tooling resin

- ISO

- 8-9

- 47

- 25-45

- 90

- 1,38

-

OT1 , OT6 - ZERO Tooling System

- Polijel 220

- Tooling gelcoat

- ISO/NPG

- Spray 11-21 / Brush 45-85

- 35

- 13-20

- 100

- 1,11

-

OT1 , OT22 - Standart Molds

- Polipol 320-TA

- Thixothropic accelerated tooling resin

- Ortho

- 4-6

- 44

- 12-20

- 81

- 1,093

-

OT1 , OT22 - Standart Molds

- Polijel 280

- High performance vinyl ester tooling gelcoat

- VE

- Spray 20-25 / Brush 50-70

- 48

- 18-22

- 115

- 1,15

-

OT1 , OT23 - ZERO Tooling System

- Polijel 291

- High thermal and chemical resistant gelcoat

- BPA

- Spray 20-25 / Brush 60-75

- 43

- 10-15

- 129

- 1,05

-

OT1 , OT23 - Acrylic Vacuum Mold

- Polipol 324-ZERO

- ZERO System / Zero shrink tooling resin

- ISO

- 8-9

- 47

- 30-40

- 105

- 1,28

-

OT1 , OT6 - ZERO Tooling System

- Polijel BC-782

- High hydrolytic resistant barrier coat

- VE

- Spray 37-41

- 40

- 14-18

- 73

- 0,8

-

OT1 , OT24 - ZERO Tooling System

- Polipol 391

- High chemical resistant bisphenolic polyester

- BPA

- 6-8

- 43

- 9-13

- 129

- 1,044

-

OT1 , OT16 - Acrylic Vacuum Mold

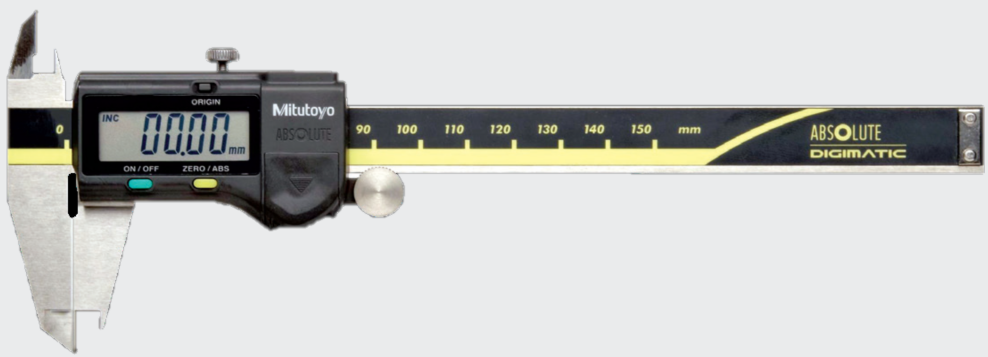

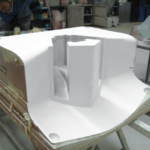

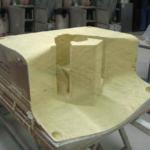

Mold Production With Zero Shrink

• Fits 100% on master pattern

• Saves overtime and labor costs

• Low styrene ratio and low styrene emission formulations provide safer working environment

• Glossy, high quality surfaces on molds

• Long lasting molds

It provides fast mold production and superior match of the mold on model. This system allows the application of resin wet-on-wet which offers faster mold production time and labor savings. It is possible to obtain high gloss, glossy molds with high mechanical endurance and chemical resistance. We recommend ZERO Tooling System for production methods like RTM and hand layup, where model-part match and surface quality are critical. The application steps of mold production are described below.

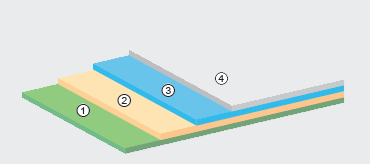

ZERO Tooling System Components

① Tooling Gelcoat Polijel 280 or Polijel 220

② Barriercoat Polijel BC-782

③ Skincoat Polives 701-TA

④ Rapid Tooling Resin Polipol 321-ZERO or 324-ZERO

Application Steps

Model Preparation

Prepare master 3D pattern of the composite part in CNC machine or 3D printer.

Preparation of Model Surface

Apply putty, primer and topcoat on master pattern surface.

Mold Release Agent Application

Apply Polivaks N and Polivaks SIVI PVA liquid mold release agent on master pattern.

Mold Gelcoat Application

Apply tooling gelcoat Polijel 280/Polijel 220 on master pattern in two layers.

Skincoat Application

Apply Polives 701-TA with glass surface veil or 225gr/m² CSM* after gelcoat.

Polyester Application

Apply Polipol 321-ZERO wet on wet with glass fibers on skin coat. It is possible to apply 6 layers of 300 gr/m² CSM* or 4 layers or 450 gr/m² CSM* of glass fibers wet on wet. After exothermic reaction, wait for the lamination to cool down and continue until the desired thickness.

Demolding

Wait 24 hours for the mold to cure on master pattern and install a frame in order to add structural stability. It is possible to demold after framing the mold.

Prepare Mold for Production

Clean the mold and polish to obtain shiny appearance.

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored