Resin Infusion Equipment and Consumables

The resin infusion process utilizes a vacuum to drive resin into a laminate. Applying laminate engineering and resin infusion technology simultaneously allows for optimization of a part in terms of strength and weight. Infusion allows production of composite parts with high reinforcement to resin ratios without any empty areas or bubbles inside the structure. The use of resin infusion is becoming a standard for boat hulls, yacht construction, wind turbine blades, bus parts and pre-engineered modular roofing where RTM or hot press methods are not applicable due to size constraints.

Resin Infusion Equipment and Consumables

The resin infusion process utilizes a vacuum to drive resin into a laminate. Applying laminate engineering and resin infusion technology simultaneously allows for optimization of a part in terms of strength and weight. Infusion allows production of composite parts with high reinforcement to resin ratios without any empty areas or bubbles inside the structure. The use of resin infusion is becoming a standard for boat hulls, yacht construction, wind turbine blades, bus parts and pre-engineered modular roofing where RTM or hot press methods are not applicable due to size constraints.

Infusion Starter Kit

The resin infusion starter kit is made for beginners to the resin infusion technology. All necessary materials are included, excluding a vacuum pump. The resin infusion starter kit will enable you to make your first composite part using the resin infusion technology in a short period of time.

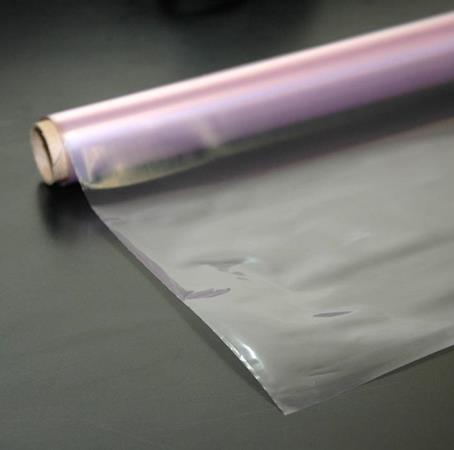

Vacuum Bagging Films

Vacuum bag film is a wide multilayer extruded film providing multiple layers of safety. These layers reduce the concerns for “pinholes”, weak spots, brittleness and inconsistency in films.

Sealant Tape

Sealant Tape is an economical multi- purpose sealant tape with high tack. It removes easily from metal or composite tools. Usable with up to 204 °C cures.

Adhesive Tape

Tac-Strip is a fiberglass fabric mesh tape coated on both sides with a ”high-tack” pressure sensitive adhesive. Tac-Strip is designed to hold dry fabrics in place as required when using resin infusion, resin transfer molding, and other processes requiring dry fabric lay-up.

Release Film / Perforated

Perforated release film is breathable, easily removed and has a “fine” textured surface for the infusion process.

Spray Adhesive

Spray adhesive bond to peel plyon reinforcement materials.

Peel Ply

A tight weave nylon peel ply coated with a silicone release agent for easy removal and a “fine” textured surface.

Resin Flow Medium/Mesh

Greenflow 185 is designed to assist resin flow through the part during the vacuum assisted resin infusion process.

Breather Fabric

Breather Fabric is polyester base on non-woven fabric used to absorb residual resins and product vacuum bag.

Fittings and Connectors

Fittings provide inexpensive and efficient through bag connection for vacuum manifold and resin feed lines for low temperature resin infusion applications.

Polyethylene Tube

Polyethylene tube is used to transfer to mold from the resin tank.

Spiral Hose

Polyethylene spiral wrap is used as a vacuum line inside vacuum baging.

Resin Flow Channel

Resin flow lines under the bag in single or double bag resin infusion applications, replacing spiral wrap polyethylene feeder lines. Omega Flow Lines incorporate an ”Omega section” internally to transport resin along the surface and into the part.

Resin Trap

Vacuum Trap (Reservoir) is designed to collect excess resin during the infusion process and prevent damage to your vacuum pump.

2.5 gallon tank size, comes complete with polyethylene liner, vacuum regulator/gage, quick disconnect coupling, and two barbed fittings for 5/8″ and 3/4″ I.D. hose.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored